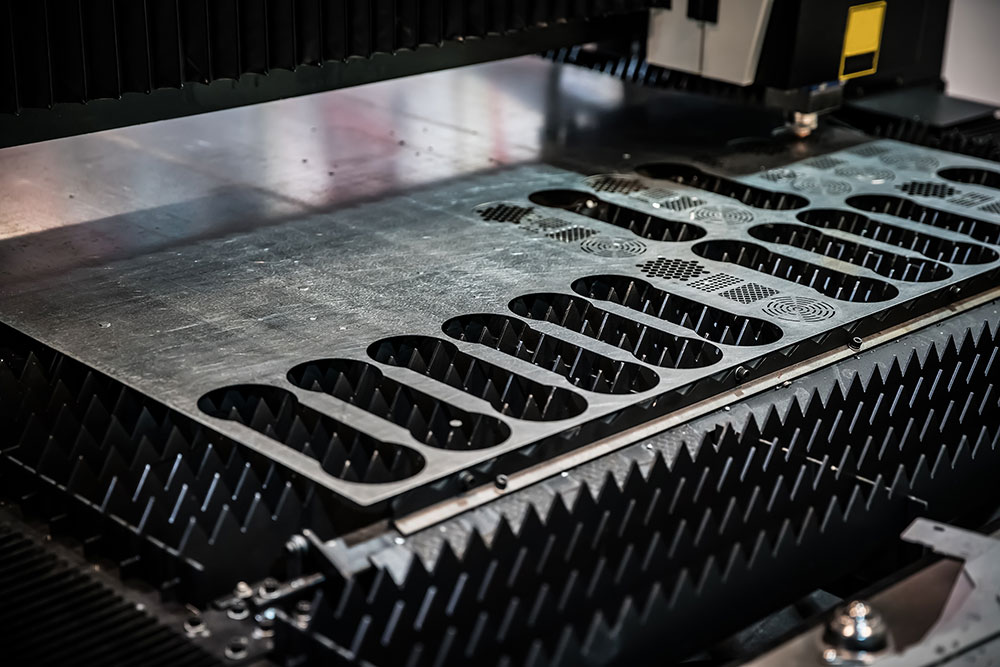

Laser Cutting

Since the inception of Laser Cutting in the 1960’s, it has constantly evolved and has revolutionised the fabrication industry. Now Laser Cutting is an integral part to many designs and projects, and at Galvin Engineering, we are here to help.

Laser Cutting is particularly important to many metal cutting projects due to its’ cost effectiveness, high accuracy, cut quality and speed. Galvin Engineering has a dedicated Laser Cutting department running multiple shifts to help reduce your overall lead time. Added to our Laser Cutting department is our dedicated Metal Folding Department incorporating up to 7 axis folding, to fold the most intricate jobs.

If you require part numbers or logo’s etched onto your parts, we can do that to! By incorporating this into the nesting software, orders can be processed quickly and efficiently, giving you exactly what you are after in a timely manner.

Our maximum sheet size is 1500 x 3000mm, with the added benefit of dual shuttle tables to help increase the output efficiencies.