Stay in the driver’s seat as drum handling is made easier with a good field of vision allowing the operator to continually observe the drum being handled. Unique manual and automatic Grab Beak designs provide a high clamping force, even when travelling over uneven ground. With few moving parts these attachments require no down time for repairs. The Lifters are suitable for standard 205 litre steel or plastic drums. Galvin Engineering always recommends you check your vehicles specifications and with the local Regulatory Authority like WorkCover to ensure any specific laws are covered when using drum handling attachments fitted to forklifts.

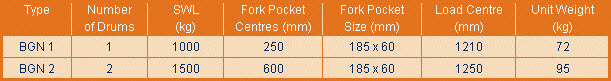

Type: BGN-1 / BGN-2 Drum Lifters

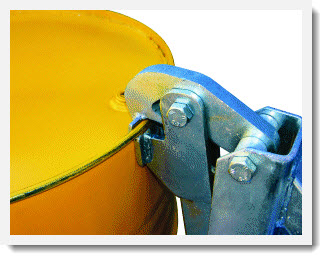

Drum handling made easy. A good field of vision allows the operator to continually observe the drum being handled. The operator does not leave the drivers seat. The unique Grab Beak design provides a high clamping force, even when travelling over uneven ground. With few moving parts this attachment requires no down time for repairs. Suitable for 205 litre steel drums, plastic drums, open top and ring lock drums.

The type BGN-1 has been designed to lift a single drum while the type BGN-2 has been designed to lift 2 drums side by side or a single drum by either Grab Beak mechanism. A contoured rest acts at a point low enough down the drum to prevent damage to the drum and its labelling.

Type: SDLC1 Drum Lifters

Designed for standard 205 litre steel drums, the fully automatic clamping action enables safe and precise placement of drums without the operator having to leave the Drivers seat. The Support Arms are adjustable to ensure secure clamping. The drum is gripped by pushing the arms against the drum centre and driving forward with the Forklift. The arms will engage around the drum and lock under the rolling hoop when raised. The heavier the load, the tighter the grip becomes. To release the drum, simply lower the drum onto ground level and reverse the Forklift.

The finish on the Drum Lifter is Zinc Plated steel.

SPECIFICATIONS:

- Safe Working Load (SWL) 500kg

- Unit Weight 100kg

- Load Centre 1375mm

- HCG 760mm

- VCG -40mm

- Pocket Size 185 x 60mm

- Pocket Centres 420mm

Type: DL1000 Drum Lifter

The safest drum lifter available. This attachment ensures 205L steel drums are moved with 100% security. The drum is quickly clamped via eccentric lock. A further safety catch prevents accidental release.

SPECIFICATIONS:

- 1000kg Safe Working Load

- Unit Weight 60kg

- Load Centre 1160mm

- Pocket Size 165 x 65mm

- Pocket Centres 335mm

Type: DR-NH Drum Rotator

Handle rotation using minimum effort for fully controlled tipping, allowing complete emptying of the drum contents.

SPECIFICATIONS:

- 500kg Safe Working Load

- 360 degree Rotation

- Unit Weight 100kg

- Load Centre 900mm

- Pocket Size 160 x 65mm

- Pocket Centres 800mm

Type: DR-NC Drum Rotator

Features hand chain operation to allow the drum to be rotated when lifted above the chest height of the operator.

SPECIFICATIONS:

- 500kg Safe Working Load

- 360 degree Rotation

- Unit Weight 90kg

- Load Centre 900mm

- Pocket Size 160 x 65mm

- Pocket Centres 800mm